Just picked up an electric blower I found on Kijiji. It’s really neat, and will be great once I have a permanent home for my forge.

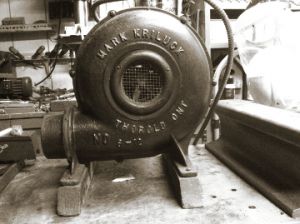

The blower itself is marked: “MARK KRILUCK THOROLD ONT NO 6-12”.

The 1/4 HP motor is marked: “DELCO MOTOR THE McKINNON INDUSTRIES, LIMITED ST. CATHARINES, ONTARIO”.

I don’t know anything about either of these companies, but the interesting thing (for me), is that both Thorold and St. Catharines are local to me. So it’s kind of nice the keep these things in the area.

However, the best part of this entire transaction, is that I met a very nice blacksmith. He’s been smithing professionally for years, and is retiring from it. He may be selling other things … an anvil, a vise, all sorts of hammers and tongs, etc. But the most valuable thing I picked up, was knowledge. An hour of chatting with this guy was pure gold!

So far, every blacksmith I’ve met has been an exceptionally nice person. I sincerely hope that trend continues.

You must be logged in to post a comment.