I’ve decided not to do too much to my crane rail after all. I may, at some point in the future, weld a piece of heavy square tubing to one end as a hardy hole … but I currently don’t weld.

I looked into having the top machined flat – but the first three machine shops I talked to all said the same thing “that’s tough stuff to work with“, and “we’re not sure our machinery is big enough to deal with that, but we may know someone” (Note: they we’re all smaller shops I’d talked to, friends of friends, etc.). I never did get an actual quote from a shop that would have taken on the work, but I assumed it would be very expensive. Money better spent on other things.

So in the end, I did a bit of ‘cleaning up’ of the rail section myself. A combination of large files, angle grinder and belt sander smoothed out the top quite a bit. It’s not ‘flat’, but isn’t too round either.

I also attempted to drill a pritchel hole. I figured that I would be doing some punching, and if I made it a bit larger (say, something a bit over a 1/2″), then I could use some basic tooling in it, such as a spring hold down. Enough to suffice until I can get a hardy holder welded on.

Well the machine shops were right about one thing, this is made of tough stuff! I don’t know if it’s case hardened or what, but there seems to be a layer within the steel, an 1/8″ or so under the surface, that just refused to drill. With my drill press on it’s lowest speed, and using lubricating oil, I just could not get a larger diameter drill bit through. I finally managed to get a very small drill bit (1/4″) through, and worked the hole up to 3/8″ with larger and larger bits – but never did get as large a diameter as I would have liked.

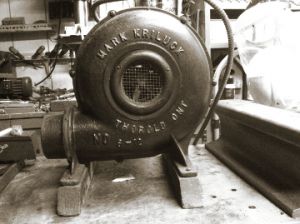

In any case, here’s the ‘finished’ improvised Crane Rail Anvil:

To quote Shrek: “That’ll do Donkey, that’ll do“.

You must be logged in to post a comment.